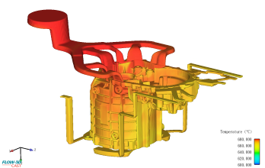

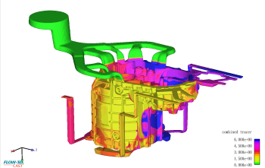

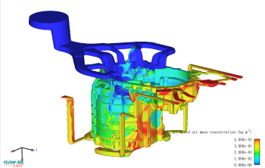

Mold design

Our experienced R&D team is capable of designing tooling and processes based on 2D drawings or 3D models. They are supported by FLOW-3D CAST, which allows for filling and solidification simulation, enabling us to provide optimal solutions for our customers.

HPDC

High Pressure Die Casting

ALTOP’s die-casting machines range from 200 to 1,350 tons, allowing us to meet most OEM company’s requirements in terms of size and weight. These machines are imported from reputable manufacturers in Taiwan, Japan, and Switzerland, ensuring high and stable performance.

Each machine has an individual mold temperature control system, with automated feeding, spraying, and fetching capabilities. We have also implemented robots to enable automated production, guaranteeing the stability of process quality and production efficiency.

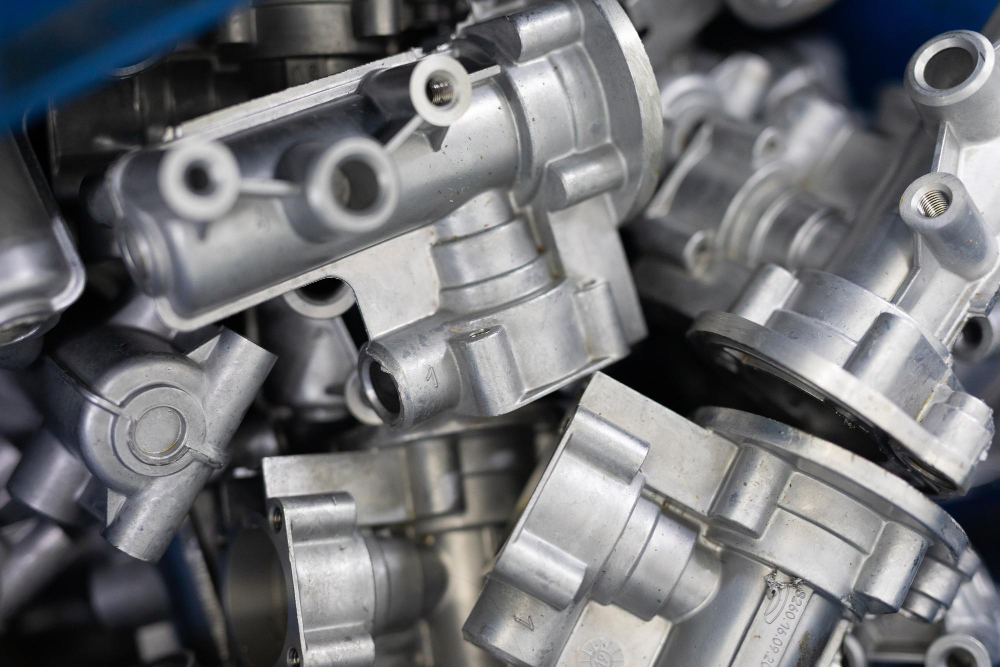

CNC Machine

Our plants have dedicated CNC lines which include vertical and horizontal CNC centers (4 axes), CNC lathes, CNC tapping centers, and multi-axial drilling machines. These advanced CNC equipment are combined with continuously optimizing process technology to achieve high machining accuracy and meet dimensional requirements.

Impregnation

Deburr&Polish

Shot blasting

Painting / Coating

ALTOP provides professional powder paint with a variety range of colors for our customers.